Welcome to the official website of Shenzhen Dankai Technology Co., Ltd.!

Sitemap | contact us | Online message | CN

Telephone:

+8615158121839Hot key words:Polyperfluoroethylene propylene(FEP/F46) PTFE Teflon series PFA PVDF

Product center

Telephone:

+8615158121839FEP winding pipe

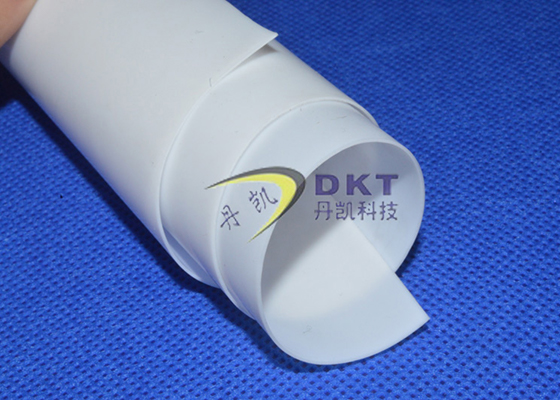

FEP winding pipe

Features of the company's products:

Excellent high temperature and low temperature performance, can be used for a long time at -200~+250℃; weather aging resistance, can be exposed to ozone and sunlight for a long time, and its surface and various properties remain basically unchanged; fire resistance otherwise, oxygen index High, non-absorbent, excellent radiation resistance, excellent dielectric properties, high voltage resistance, and high insulation.

Excellent corrosion resistance, only the elemental fluorine and alkali metals at high temperature have an effect on it, and it has no effect on all other concentrated and dilute inorganic organic acids, alkalis, and esters.

Good wear resistance, static friction coefficient is the smallest among plastics, excellent self-lubricating performance, unique surface non-stickiness; good tensile strength.

Ease of secondary processing: self-sealing, self-welding, flanging, and coiled tube can be made.

Widely used in: aerospace, instrumentation, medical and pharmaceutical, electronic appliances, post and telecommunications, petrochemicals, metallurgical power, household appliances, lighting, etc.

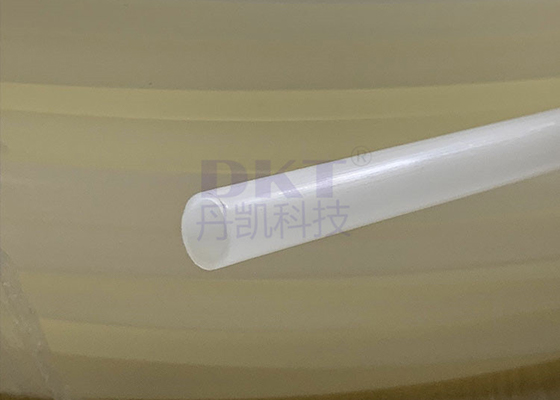

Product introduction of winding tube:

The material of the winding tube: made of FEP PFA PTFE material.

How to use the winding tube: first fix one end of the starting point with a protective tape, and then tighten it in a clockwise direction to bundle the wires together.

The purpose of the winding tube: It is used to protect the wire from abrasion and insulation, and can improve the appearance of the wire bending.

Product features of winding pipe:

1. Good hand feeling, no peculiar smell 2. High temperature resistance 3. High insulation

4. Wear-resistant 5. Flame-retardant 6. Anti-aging

7. Environmental protection 8. Tensile resistance 9. Flame resistance

10. High pressure resistance

The purpose of winding pipe:

1. Optical fiber protective cover

2. Cable protection

3. Wire protection

4. Protective cover for lighting equipment

Use and installation method of winding pipe

The use and installation of winding pipes are divided into machine installation and manual installation. The installation of the machine requires equipment similar to the hose water cloth winding machine. The manual installation is as follows:

1. Rotate the middle part of the hose (wire, cable) to the middle part of the flame-retardant winding tube, and start from the wound middle part to one end of the hose (wire, cable).

2. Take one end of the hose (wire, cable) around the winding tube and locate it at the joint of the hose (wire, cable). After positioning, reverse the spiral protective sleeve and loosen it, you can move it at will, and start to revolve from the middle part of the wound to the other end.

3. Wrap both ends of the flame-retardant winding pipe around the outside of the hose (wire, cable), and the installation is complete.

Note: Multiple wires and cables can be branched for installation and use.

Main application areas of winding pipe

Winding pipe is mainly used in various engineering machinery and mining hydraulic equipment and the protection of wires and cables with abrasion resistance requirements. Because it can completely cover the product to be protected, it forms an effective abrasion and anti-ultraviolet protective effect, which protects many rods.

Recommended products

Online Inquiry

Landline: 0755-29979617

Cell phone: 15818669373

Add WeChat, free sample

Follow the corporate public account

Shenzhen Dankai Technology Co., Ltd.

Address: Area B, 4th Floor, Building 1, North Yongfa Science and Technology Park, Yanchuan North, Chaoyang Road, Songgang Town, Bao'an District, Shenzhen

Tel: 0755-29979617 23127719 23127819

Fax: 86-0755-29979492

Follow us

Page copyright©1998-2024 Shenzhen Dan Kai Technology Co., Ltd. Guangdong